"THE PROCESS"

GARAGE FLOOR COATINGS INSTALLER

Polyaspartic / Polyurea

Residential, Commercial or Industrial Installation

STEP1 - MECHANICAL DRY DIAMOND GRIND THE CONCRETE SUBSTRATE FOR PROPER PROFILING AND MAXIMUM COATING ADHESION.

The entire grage floor surface is ground down, which properly profiles the substrate and opens the pores of the concrete. Hand grinders with diamond cup wheels are used around the perimiter's edges and also around any obstructions like poles or water heaters, etc. to make sure every square inch of the floor is properly profiled.

Vertical surfaces like foundation walls, cinder blocks, steps, and wood baseboards can have the coating applied as well, which adds to the aesthetics of the overall floor coating.

STEP 2 CRACKS, PITTING AND ANY IMPERFECTIONS ARE REPAIRED.

Other imperfections and types of minor damage that will naturally be found on concrete floors also need to be repaired during the garage floor coating process.

Once the grinding process is finished and the floor is completely smooth, we will then thoroughly vacuum the entire floor surface to remove any and all debris from the concrete substrate and the surface area wall then be ready to apply the Polyaspartic Polyurea primer/base coat.

STEP 3 - APPLY THE TINTED POLYASPARTIC POLYUREA PRIMER/BASE COAT.

The two-component Polyaspartic Polyurea primer/basecoat will then be applied to the floor using a 3/8 nap phenolic 18 inch roller followed by a cross roll and then a back roll in the opposite direction. This Polyaspartic Polyurea primer/basecoat has tinted pigment added that matches the pre-blended flakes the customer has chosen. we have 100’s of chip blend colors to choose from.

All vertical surfaces like knee walls will have the base coat roll applied to the surface along with a full broadcast of the selected chip aggregate applied.

STEP 4 - BROADCAST TO "FULL REJECTION" A COLOR FLAKES CHIP BLEND

Team Fortress Floor Coatings will broadcast the 1/4 inch decorative vinyl flakes into the wet primer/base coat. We broadcast 2-3 times the amount of flakes on the floor during this process to ensure 100% coverage.

Now that the entire floor is coated and flaked, 60 minutes is required to let the coating cure. At that point, we remove the excess flake material using a flat metal edge floor scraper to knock down any vertical standing flakes which are then followed up with a thorough vacuum of the entire floor surface to remove all remaining debris. The floor is now ready for the clear, high-gloss Polyaspartic Polyurea top coat sealer.

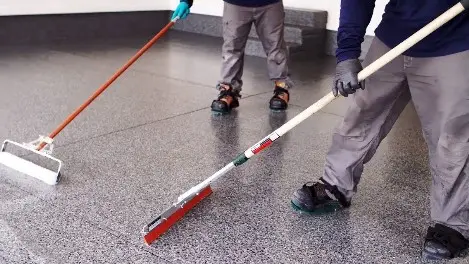

STEP 5 - APPLY THE CLEAR, HIGH-GLOSS POLYASPARTIC POLYUREA TOP COAT SEALER

Now that your floor has been prepped, coated, flaked, scraped, and vacuumed, Team Fortress Floor Coatings can start our final step – the application of our Clear, High-Gloss Polyaspartic Polyurea 100% UV Stable top coat sealer. We pour the mixed product directly onto the floor and use a soft squeegee to spread the coating to our desired thickness. We then use an 18-inch roller to back and cross roll the floor. This takes out any lines left behind by the squeegee and leaves a fine, glossy, clear coat finish over the entire floor. Your floor is now a seamless, monolithic, showroom quality area that you can be proud of for a very long time. Go ahead, Show it off to all your friends, neighbors and co-workers, they will want one too!

FLOOR FOR ALL GARAGES

EXHIBITION FLOOR

MULTI-FUNCTION GARAGE

INSTITUTIONAL GARAGE

WAREHOUSE FLOOR

FLOOR FOR WORK

FREE QUOTE

You need a price or more information about our products, do not hesiate to contact us, we are here to help you achieve your goal.

LEADER IN GARAGE FLOOR COATINGS